Mastering Stove Temperature Control for Reliable Camp Cooking

Precise stove temperature control is the foundation of reliable backcountry food preparation. When operating a camp cooking stove in challenging conditions (from high-altitude environments to sub-zero winter camps), understanding and managing heat output becomes critical for safety, efficiency, and meal quality. This FAQ provides evidence-based methods for temperature regulation that account for fuel states, environmental variables, and operational constraints, determining whether your kitchen system succeeds or fails when conditions demand flawless execution.

Why Temperature Control Matters More Than Raw Power

How does ambient temperature affect stove performance?

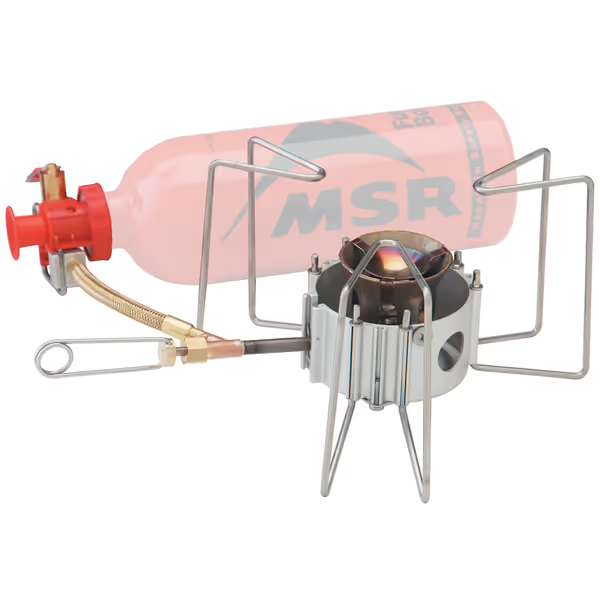

Fuel state directly determines stove output. At or below 0°F (-18°C), standard upright canister stoves experience pressure drop as propane depletes from the fuel mix, creating a runaway cooling effect through latent heat of vaporization. This phenomenon, documented in field studies, causes canister temperatures to fall 10-15°F below ambient as fuel boils. For cold-weather reliability, see our canister stove cold-weather strategies. Liquid fuels like white gas maintain consistent pressure down to -40°F, but require proper priming to reach operating temperature. The MSR Dragonfly stove exemplifies precision engineering for this challenge with its dual-valve design that maintains stable output across temperature extremes.

MSR Dragonfly Compact Liquid Fuel Camping and Backpacking Stove

Risk mitigation: Always pre-warm your canister in freezing conditions by carrying it inside your jacket or placing it in a shallow bowl of 100°F water during operation. For liquid fuel systems, conduct a controlled priming away from your shelter (never near soft goods), using a dedicated priming cup. Remember: Cold punishes mistakes; redundancy and priming keep kitchens alive.

What techniques provide effective flame regulation outdoors?

Advanced flame regulation outdoors requires understanding both your stove's mechanical limitations and environmental variables. On liquid fuel stoves like the Dragonfly, gradual valve adjustment prevents fuel surges while maintaining proper pressure in the generator tube. For propane systems, dialing back the regulator slowly prevents sudden temperature drops that cause incomplete combustion.

With canister stoves, inverted positioning maintains liquid feed and consistent pressure below freezing. At -20°F, we once needed 5 liters of water by dawn, while nearby teams battled frozen regulators. Our inverted canister system performed flawlessly because we'd pre-warmed the fuel and positioned it away from snow contact. The margin wasn't luxury, it was safety. Separate melt and brew cycles to prevent temperature fluctuations that compromise both processes.

Achieving Precision in Variable Conditions

How can I achieve true simmering mastery while camping?

True simmering requires thermal stability, not just reduced flame. At elevation above 8,000 feet, water boils at 197°F instead of 212°F, making a gentle simmer impossible with standard techniques. Implement these field-proven approaches:

- Widened fuel valve control: Liquid fuel stoves with multi-position valves (like the Dragonfly's dual-valve system) provide precise output adjustment

- Intermediate heat sinks: Place a flat rock beneath your pot to diffuse direct flame

- Regulated wind exposure: Position your stove so wind affects only 30% of the flame envelope

- Temperature monitoring: Use a clip-on thermometer calibrated for outdoor use

Flame regulation isn't about reducing heat, it's about managing thermal transfer to your cookware. A stable 180°F simmer requires different techniques at 10,000 feet than at sea level.

What heat zone management strategies prevent burning while maintaining efficiency?

Heat zone management requires understanding thermal dynamics in your cooking environment. At 12,000 feet with 15 mph winds, your effective heat output drops 40% even with a proper windscreen. Implement these strategies:

- Create concentric heat zones by arranging fuel sources in rings

- Rotate cookware 90° every 2 minutes to counteract wind-directional heating

- Use larger diameter pots on narrow burners to widen the thermal footprint

- Position cooking stations perpendicular to prevailing winds

For group cooking, maintain separate stations for melting and brewing. At 0°F, melting snow consumes 80% of your thermal energy, diverting this process from your meal preparation station prevents constant temperature cycling that wastes fuel and creates burn hazards.

Altitude, Safety, and System Design

How does altitude impact camp cooking stove performance?

Above 5,000 feet, reduced atmospheric pressure decreases boiling points by approximately 1°F per 500-foot elevation gain. This creates two critical effects:

- Extended cooking times (add 1 minute per 1,000 feet above 5,000 feet)

- Reduced thermal efficiency requiring compensatory fuel calculations

At 14,000 feet, water boils at 184°F, making sterilization impossible through boiling alone. For gear choices that still perform above 10,000 feet, see our high-altitude stove comparison. Use insulated cookware and always maintain a lid during heating to capture 30% more thermal energy. Pressure-regulated canister stoves compensate partially for altitude effects but require additional pre-warming below 20°F.

What safety considerations relate to temperature control?

Improper temperature management creates multiple hazards: For comprehensive protocols, read our camp stove safety guide.

- Carbon monoxide buildup from incomplete combustion in low-oxygen environments

- Unstable thermal transitions causing flare-ups during fuel adjustment

- Condensation-related failures when moving warm stoves into freezing conditions

Mitigation protocols:

- Never operate stoves inside enclosed spaces (even vestibules during storms)

- Allow 30 seconds between significant fuel adjustments to prevent fuel pooling

- Store backup fuel canisters at consistent temperatures to prevent pressure spikes

- Maintain minimum 3-foot clearance from all combustible materials

Advancing Your Camp Kitchen Capabilities

What constitutes truly advanced camp cooking skills?

Advanced camp cooking skills extend beyond basic flame adjustment to include predictive temperature management. This includes:

- Anticipating thermal lag between control adjustment and temperature change

- Understanding fuel mix depletion curves in canister systems

- Calibrating cook times for specific pot-stove combinations

- Recognizing visual flame indicators of optimal combustion

Document your stove's performance across temperature ranges, altitudes, and wind conditions. This tracking becomes your field reference for simmering mastery while camping in changing conditions. Winter systems require additional protocols: test your inverted canister technique at progressively lower temperatures before committing to it in extreme cold.

The most reliable kitchens operate with disciplined redundancy. Carry two stove types when feasible (one optimized for melting, another for cooking), and document your fuel consumption meticulously. At -15°F, you don't have time for experimentation; you need systems you can operate flawlessly.

Actionable Next Step

Select one temperature control technique relevant to your next trip and practice it 3 times in controlled conditions before your expedition. For winter trips, focus on inverted canister operation with a warm water bath backup; for high-altitude excursions, perfect your wind management protocol. Document your observations in a dedicated stove log, note ambient temperature, altitude, wind conditions, and fuel consumption. This systematic approach transforms stove temperature control from reactive troubleshooting to predictive capability, ensuring your camp kitchen performs when it matters most. Remember: In winter, the safest stove is the one you can operate flawlessly, invest the time to make yours that system.